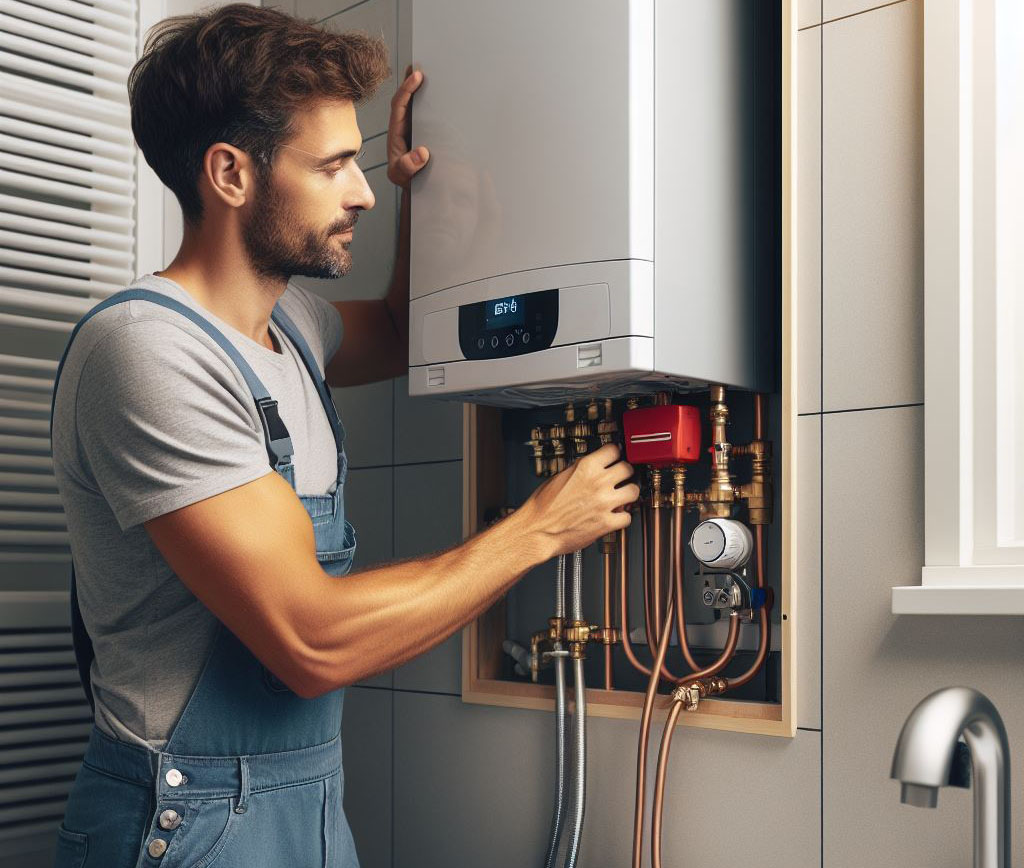

In the realm of home heating and hot water systems, combi boilers stand out as a beacon of innovation and efficiency. These units, compact and multifunctional, serve the dual purpose of warming your home while providing an endless supply of hot water. The key to unlocking their full potential lies in the installation process. A well-executed installation not only guarantees optimal performance but also ensures safety, maximizes energy efficiency, and prolongs the system’s lifespan. This is a task that demands precision, understanding, and respect for the intricacies of the system.

Understanding Combi Boilers

Combi boilers represent a significant leap forward in heating technology. Unlike traditional systems, which rely on bulky tanks and separate heating mechanisms, combi boilers are designed to heat water directly from the mains on demand. This means no waiting time for hot water and a significant reduction in energy wastage. The efficiency of these systems is unparalleled when compared to their predecessors. They require less space, reduce energy bills, and provide a seamless supply of hot water and heating, making them an ideal choice for modern homes.

Pre-Installation Considerations

Embarking on the installation of a combi boiler is not to be taken lightly. It is a process that necessitates thorough preparation, the right tools, and a keen awareness of legal and safety requirements.

- Assessing Suitability: First and foremost, evaluate whether a combi boiler is the right fit for your home. Consider the demands of your household, particularly in terms of water usage and the existing water pressure. Combi boilers are best suited for environments where space is at a premium and the demand for simultaneous hot water use is moderate.

- Gathering Tools and Materials: The installation of a combi boiler is a hands-on task that requires a specific set of tools. Essential items include pipe cutters for precise cuts, wrenches for tightening connections, soldering equipment for secure joints, and safety equipment to protect against potential hazards. Each tool plays a critical role in ensuring the installation process is smooth and efficient.

- Navigating Legal and Safety Requirements: The installation of a combi boiler is governed by local codes and regulations, particularly when it involves gas connections. It’s imperative to obtain the necessary permits and ensure that all aspects of the installation comply with these regulations. For gas-related tasks, enlist the expertise of a certified professional to guarantee the safety and legality of the installation.

Step-by-Step Installation Guide

Preparation: Clearing the stage is your first order of business. This involves the meticulous removal of any outdated equipment – from ancient boilers to unused tanks. It’s about creating a clean canvas for your new installation, ensuring there are no remnants of the past to interfere with the efficiency of your new combi boiler.

Positioning the Boiler: Selecting the ideal location for your boiler is more art than science. You’re aiming for a balance of accessibility, functionality, and compliance with ventilation requirements. A good rule of thumb is to choose a spot that simplifies future maintenance and is conveniently close to gas and water connections, all while ensuring the exhaust can be safely directed outdoors.

Connecting Water Supply: Plumbing takes center stage as you connect the boiler to the cold water supply. This step demands precision and attention to detail. Opt for high-quality fittings to avoid future headaches, and remember the old adage: measure twice, cut once. Ensuring a leak-proof connection here is paramount for the system’s long-term reliability.

Gas Supply Connection: Gas work is not a DIY endeavor unless you’re certified. The risks associated with improper gas connections are severe, ranging from leaks to potential explosions. Enlisting a certified professional ensures your installation adheres to safety standards and local regulations, providing peace of mind and safeguarding your home.

Electrical Work: Wiring your combi boiler is a critical phase where expertise in electrical systems is indispensable. If you’re not thoroughly versed in electrical work, hiring an electrician is advisable. They will ensure the boiler is correctly and safely connected, avoiding any risk of electrical mishaps.

Venting and Flue Installation: Proper ventilation is crucial for the safe operation of your combi boiler. This step involves adhering strictly to the manufacturer’s guidelines and local building codes. Proper flue installation ensures harmful gases are safely expelled from your home, preventing potential health risks.

Final Checks and Testing: Before your boiler’s inaugural run, a comprehensive series of checks and tests is essential. This includes pressure checks and leak detection to verify the integrity of the installation. Only after thorough testing should you initiate the boiler, closely monitoring its first cycles to ensure everything operates as expected.

Maintenance Tips

Consistent maintenance is the linchpin of your combi boiler’s longevity and efficiency. An annual inspection by a qualified technician can preempt issues by identifying wear and tear early on. Think of it as a health check-up for your boiler, ensuring it continues to operate at peak performance.

Safety Considerations

Safety cannot be overstated in the context of combi boiler installation. The integration of gas and electricity introduces inherent risks, underscoring the importance of carbon monoxide detectors and adherence to safety protocols. Always prioritize safety by following established guidelines and opting for professional assistance when necessary.

FAQ Section

The fundamental distinction lies in their operation, combi boilers provide hot water on demand without the need for storage tanks, setting them apart from traditional systems.

While certain aspects of the installation might be within the ambit of a skilled DIYer, gas and electrical connections should invariably be handled by certified professionals.

A straightforward installation can be completed within one to two days, though it’s wise to account for potential complexities.

Indicators such as unusual noises, leaks, or a decline in heating efficiency signal the need for maintenance or possibly replacement.

Yes, their on-demand heating capability significantly reduces energy waste, making them more efficient than traditional systems.

Immediately turn off the boiler and consult a professional. Attempting to address the issue without the requisite expertise can exacerbate the problem.